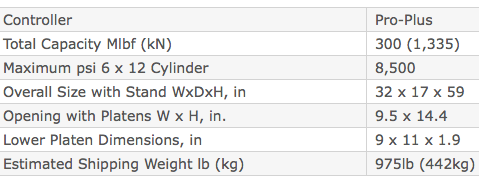

With solid steel cross-heads from 3-6in (76-152mm) thick on our standard frames, Gilson load frames are the stiffest in the industry. The frame is among the few meeting the stringent ACI 363 rigidity recommendations. This 300,000lbs (1,334kN) Concrete Compression Testing Machine is equipped for testing 6x12in (152x302mm) cylinders, but may be outfitted with accessories to accommodate many different sized cubes, cores, beams and cylinders. The Load Frame Mounting Stand is optional for this unit. The mounting stand is placed in the lower platen at the correct height for safe, efficient handling of specimens. Includes latchable steel Fragment Guard Doors. The controllers is side-mounted.

The bottom mounted hydraulic ram applies compression force upward. Precision ground piston with O-Ring sealing and Teflon back-up ring rests in a polished steel cylinder. Spherically-seated upper platen assemblies are ground, hardened, nickel plated and scribed with concentric circles and oversized rectangular compression tables. Locking stem holds upper platen assembly securely in place, yet allows for quick substitution of accessory components.

The two-stage, oil-immersed pump drives the hydraulic systems. The first high volume, low-pressure stage rapidly advances the piston. The pump automatically switches at 135psi of pressure to the second stage of low volume, high pressure flow used during testing to maintain a continuous rate of loading from 2,000-200,000lbf per minute with the value set in its Metered Advance Position. Hold feature pauses pressure advance indefinitely and Retract feature releases pressure to allow return of piston to starting position. A high-pressure hydraulic safety valve prevents use beyond maximum machine capacity. A pressure bleed hole in the piston helps avoid overextension of the ram. Our unique 1/2hp system runs cooler and offers better load control and is the quietest available. Operates on 115V/60Hz power supply.

The Pro-Plus controller offers the most accurate and advanced system available today for the testing and documentation of concrete strengths. Ease of operation and dependability are two important features of this new system. All information is clearly displayed on the 4.6x3.4in (116x86mm), WxH back-lit VGA graphic panel. The large 320x240 pixel screen with large alphanumeric characters has adjustable contrast to make it easily readable under any lighting conditions.

Soft-key menus allow fast and easy set up. A sample type menu lists six common specimen and test types: cylinder, cube, third-point and center-point beams, cylinder-split and cross-sectional area. Test results are automatically stored for hard-copy documentation. In case of accidental data loss, a calibration restore feature allows the original factory calibration to be uploaded to the controller via a communication port. The original calibration data file is maintained at the factory.

During a test cycle, load, stress and rate of load in the time units selected are displayed simultaneously. At test completion, peak stress, load, and if activated, the average loading rate during the test, are automatically displayed. Selectable engineering units include Force: lb, kN, kg and N; Stress: psi, mPa, kg/cm2, and kPa; Size: in, mm, and cm; and Time in seconds or minutes. The Pro-Plus also features live X-Y plotting of load vs. time.

The controller can automatically store test results to memory for downloading to a printer, or to a PC for further recording and reporting options. Up to 500 tests can be stored to memory and printed in a spreadsheet format listing test date and time, sample ID number, sample type, specimen area and length, peak load and peak stress. Optional data includes average rate of load, C 39 cylinder correction factor, break type, cylinder cap type, sample age, weight, and operator ID number. Spanish or English language menus can be toggled in the settings. Inquire for other options to store and download test data.

The Pro-Plus has a two-year warranty and is built for harsh laboratory environments and features a stainless steel NEMA-4 enclosure that is both moisture and dust proof. Heavy-duty tactile keys are tested to over five million actuations. Accuracy is achieved through a five-point linear calibration program to exceed ASTM C 39 and E 4 requirements and in general, is better than ±0.5% of indicated load from 1% to machine capacity. The Pro-Plus Controller is also UL, CUL, CE, and Measurement Canada listed.

Meets Test Methods:

AASHTO T 22

ASTM C 39

ASTM E 4

BS 1610

BS 1881